The newest and last of the American Box Company mIlls (American Forest Products Corp) in Calaveras County, was the Associated Lumber and Box Company mill at Sandy Gulch. A new community was built to serve the mill workers and their families. Houses consisting of 4 rooms were built around a central area. This community was named Wilseyville in honor of Lawrence Wilsey, General Manager of the three Calaveras County Mills. These houses complete with water, electricity, and sewer rented for $25 per month. The mill was regarded as very well designed and modern. An example of the careful planning was that the mill pond was only eight inches below the mill level, so logs didn’t have to be lifted far in order to get them into the mill Ground was broken for the mill site in December 1942, and mill construction started in April of 1943. Stockton Box handled the logging and transportation to this mill as well as their own. (Editor’s note: We now have a photo of an Associated Lumber truck being loaded with logs, so this what has been said about the arrangement with Stockto Box can’t be totally true.) John Parmeter was the woods boss and J.D. conger the yard boss. Howard Blagen was the resident manager of the mill. The mill featured these mechanical features and attributes, at least when it opened. The mill is all electric 9 foot Allis Chalmers Band Mill All steel carriage with Trout Set Forks and Martin Air Dogs 14 inch Shot Gun Feed Hill Nigger and Log Kicker 84 inch Mershon Vertical Resaw with Merrry-Go-Round 72 inch edger 4 boilers- 2 for mill operation and 2 for dry kilns to be installed later (editors note: I don’t know if the kilns were added or not) Operating crew- 125 men working 2 shifts Boilers fueled by sawdust and hog fuel Approx. cut per shift, 100,000 Height of stacks – 130 feet 2 acre pond holding 1 million cubic feet of water Average haul of lumber- 9 miles An operational method, new at least to Central California, was that the lumber was handled by the “unit package” system. This eliminated the old style square piles. Lumber was handled by lift trucks and carriers entirely. Solid packages were taken from the green chain to the automatic stacker where they were “sticked” for drying. After drying, these packages were put thru the unstacker where the stickers were taken out and the piles made ready for shipment.

Associated Lumber and Box Mill at Sandy Gulch mid 1940’s (Click to enlarge)

Associated Lumber and Box Mill Sandy Gulch April 1944 (Click to enlarge)

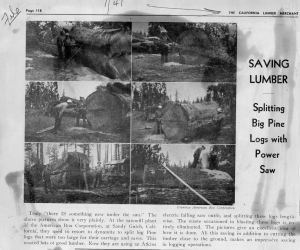

Interesting story about a new tool at Sandy Gulch

Workers at Sandy Gulch (probably mid 40’s) (Click to enlarge)

Workers at Sandy Gulch (probably mid 40’s) (Click to enlarge)

Employee home at Wilseyville (Area near Sandy Gulch where employee homes were built) (Click to enlarge)

Lonnie Hertzig (American Eagle (company publication) gives much of the credit for putting the mill together to Lonnie

Lonnie Hertzig (American Eagle (company publication) gives much of the credit for putting the mill together to Lonnie

Jim McGrew (editor doesn’t know what his job was)

Jim McGrew (editor doesn’t know what his job was)

This page has the following sub pages.

Leave a comment